Company Details

Company Details

1, The choice of pressure and speed

The choice of injection specific pressure for Die Casting process Die Casting Machining should be determined according to different alloy and casting structural characteristics. For the selection of filling speed, generally for castings with thick walls or higher internal quality requirements, lower filling speed and high pressure should be selected. or thin wall or high surface quality castings and complex castings, a higher proportion and a higher filling rate should be selected.

2, Casting temperature

Casting temperature refers to the average temperature of liquid metal when it enters the mold cavity from the pressuring chamber. Because it is inconvenient to measure the temperature of liquid metal in the pressuring chamber, it is generally expressed by the temperature in the holding furnace.

The casting temperature is too high, the shrinkage is large, the casting is easy to produce cracks, the grain size is large, but also can cause the sticky type. If the casting source is too low, it is easy to produce defects such as cold separation, surface pattern and insufficient pouring. Therefore, casting temperature should be considered together with pressure, die Casting Mold temperature and filling speed.

3, The temperature of the die casting mold

Casting pressure type should be preheated to a certain temperature before use, generally use gas, blowtorch, electrical appliances or induction heating.

In continuous production, die casting mold temperature often rises, especially die casting high melting point alloy, rising quickly. Excessive temperature causes the liquid metal to produce viscous type, the casting cooling is slow, and the grain size is coarse. Therefore, cooling measures should be taken when the die casting mold temperature is too high. Cooling is usually done with compressed air, water, or a chemical medium.

Shenzhen SCZY Technology Co., Ltd

Business Type: Manufacturer

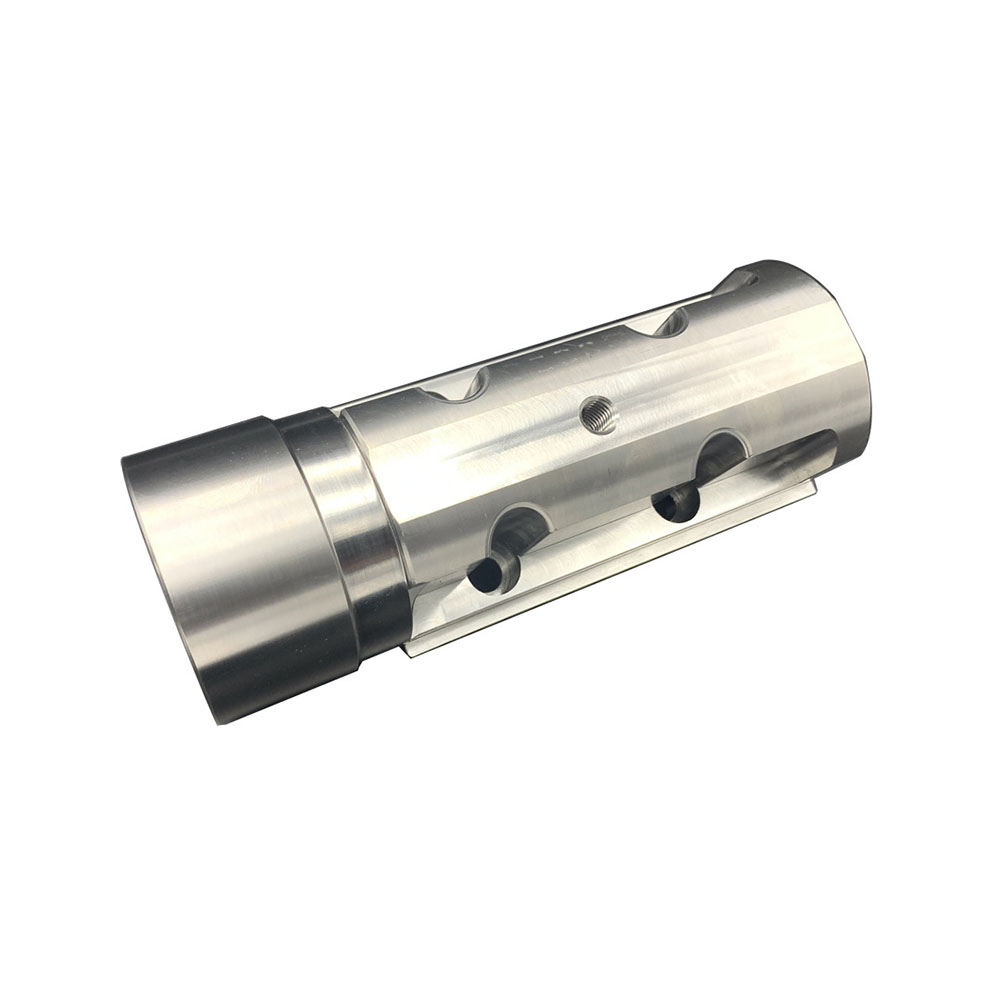

Product Range: CNC Machining , CNC Machining Parts , Precision Machining, CNC Milling Parts, CNC Turning Parts, Machining, Forging, Forging Parts, Investment Casting, Die Casting, Casting Parts, Sheet Metal Fabrication, Product Assembly Service...

Tel: +86-769-81582278

Mobile: +86 189 2921 5001 (WhatsApp/WeChat)

Email: sandy@sczyltd.com

Address: No. 1906, Vanke Center, Changqing South Road, Chang` An Town, Dong Guan City, Guangdong Province, PR China 523850