Company Details

Company Details

![]() December 01, 2021

December 01, 2021

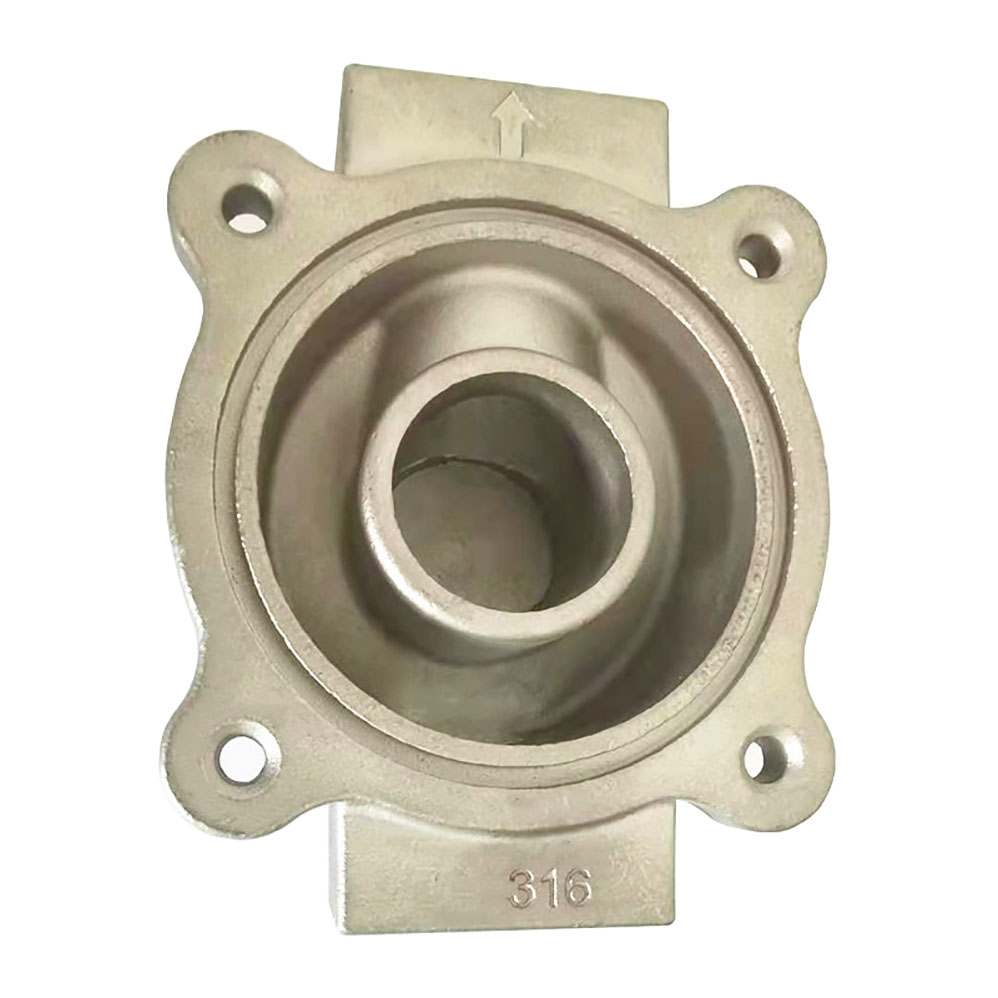

We made a lot of Investment Casting Parts, as well as Die Casting Mold Development. But what is the process? Casting molding generally does not apply pressure, the strength of the equipment and mold is not high, the size of the product is small, the internal stress in the product is low. Therefore, the production investment is less, can be made of good performance of large parts, but the production cycle is longer, after molding must be machined. On the basis of traditional casting, the methods of casting, inlay casting, Pressure Casting, rotary casting and centrifugal casting are derived.

⑤ Centrifugal casting: A quantity of liquid material is injected into the mould which rotates at a high speed and can be heated, and the material is distributed to the inner wall of the mould cavity by centrifugal force. After physical or chemical action, the product is solidified into tubular or hollow tubular products (see figure [centrifugal casting]). Monomer casting nylon parts can also be formed by centrifugal casting.

Product Range: CNC Machining , CNC Machining Parts , Precision Machining, CNC Milling , CNC Turning Parts , Machining, Forging, Forging Parts, Investment Casting, Die Casting , Casting Parts, Sheet Metal Fabrication, Product Assembly Service...

Tel: +86-769-81582278

Mobile: +86 189 2921 5001 (WhatsApp/WeChat)

Email: sandy@sczyltd.com

Address: No. 1906, Vanke Center, Changqing South Road, Chang` An Town, Dong Guan City, Guangdong Province, PR China 523850

The above is the Process introduction of casting we have listed for you. You can submit the following form to obtain more industry information we provide for you.

You can visit our website or contact us, and we will provide the latest consultation and solutions

Send Inquiry

Most Popular

lastest New

Send Inquiry