Company Details

Company Details

Whether CNC Machining is difficult or simple is a scientific question worth exploring. In fact, there are many classifications of CNC machining, CNC milling (CNC three axis machining, CNC four axis machining, CNC five axis machining, etc.), CNC turning and milling, CNC turning and milling combined machining, CNC grinding and so on. It is to determine the processing plan according to the product structure, surface requirements and accuracy requirements, etc. There are also different machining difficulties for different materials. For example, titanium Precision Machining Parts and 316 stainless steel machining parts are more difficult to machine, while aluminum CNC Machining Parts, copper CNC machining parts or plastic CNC machining parts are easier to process. For our CNC processors, the most difficult part is the structure and accuracy requirements of the workpiece. The more complex the structure of the workpiece and the higher the accuracy requirements, the more difficult it is to process.

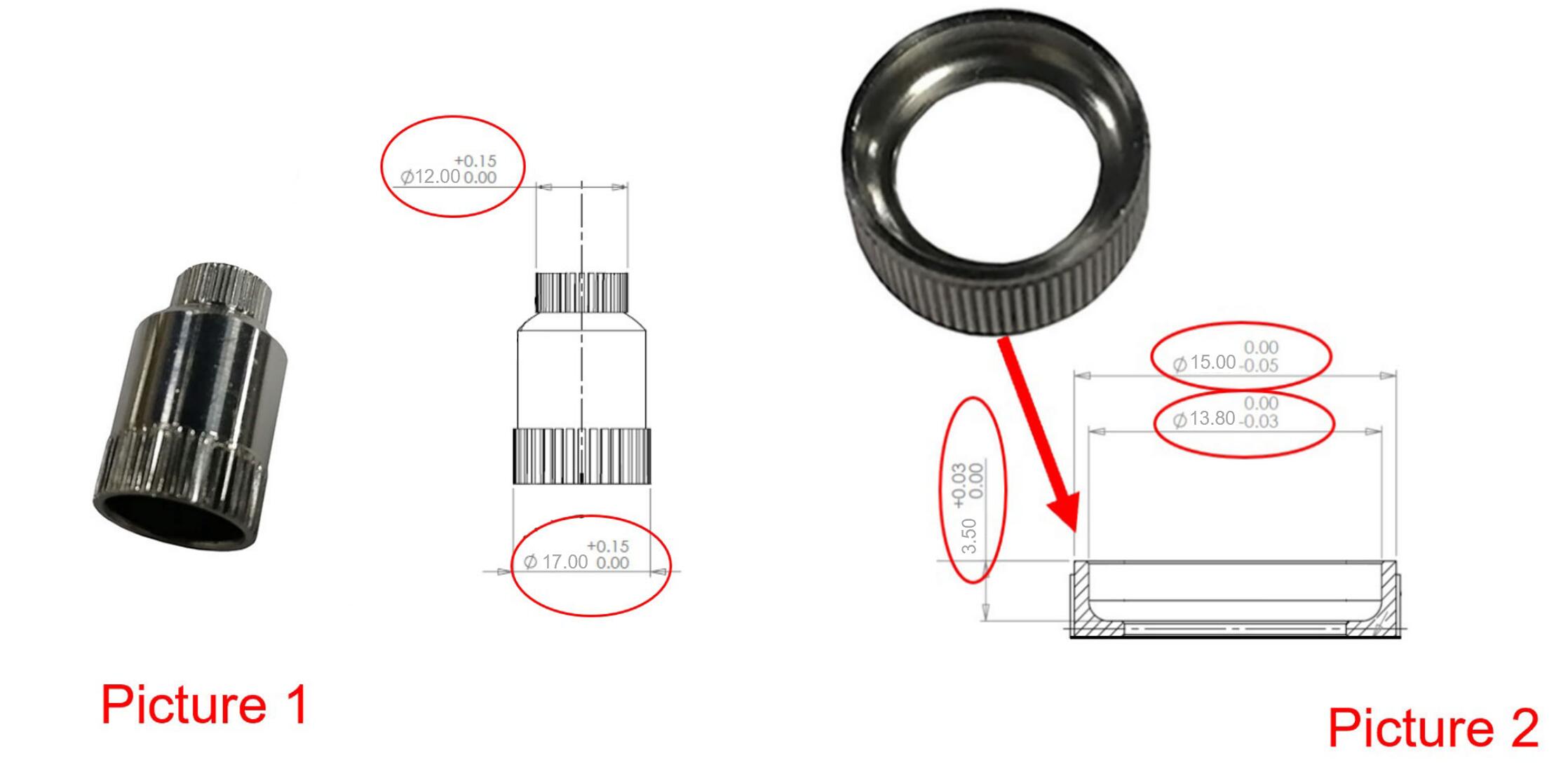

Next, we will analyze the different processing difficulties of different products based on examples. As shown in the figure below, both products are CNC turning parts, and the materials are also stainless steel 316. However, because the tolerance requirements of the product in Figure 1 are not high, the processing is very easy, and it is knurled directly after CNC turning; and for the product in Figure 2 because the tolerance requirements are relatively high (some dimensions require ±0.01mm), and two-end processing is required. To ensure a tolerance of ±0.01mm, we need to customize a chuck to ensure the clamping and ensure the machining accuracy; and since the wear of the tool will also affect the machining accuracy, it is necessary to continuously check during the machining process to ensure that the products are all qualified .

Therefore, the difficulty of CNC machining has a lot to do with the machine equipment and the tool itself, as well as the operator's technical level and the level of fixture production. Only with good equipment and high level of master can we make high-precision Precision Machined parts.

SCZY has more than 10 years of rich experience in this field. If you need to know more about metal CNC or plastic CNC precision machining parts, please send an email to: info@sczyltd.com